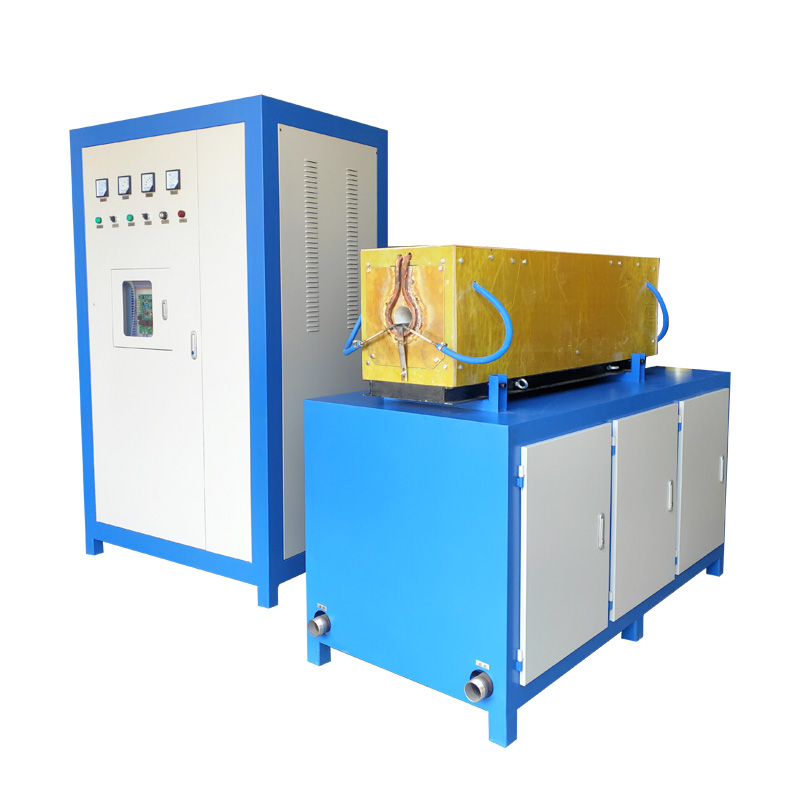

Product Specifications: High Frequency Induction Heating Equipment Series Power RAC-80KW

Product features: adjustable power, induction heating, fast heating, high efficiency, easy temperature control, wide heating range, strong applicability, only metal induction, safety, energy saving and environmental protection!

Product packaging: wooden box packaging

Product application: various round steel, square steel, bar stock, round cake, round pipe, steel plate, steel ring, fasteners, high-strength bolts and nuts, automobile U-bolts and nuts, stainless steel bolts and nuts, bolts and nuts, bearing rings , Flange, cross shaft, flange fork, universal joint and other workpieces for diathermy forging.

1. Main Features

1. It is used for heating various carbon steel, iron and other bars;

2. High-frequency heating of bars below Φ45 is more diathermic, more uniform and faster;

3. Ultra-small size, movable, covers an area of only 2 square meters, convenient to use with any forging and rolling equipment;

4. Induction heating makes the bar heated to the required temperature in a very short time, greatly reducing metal oxidation, saving material and improving forging quality;

5. Automatic feeding; power saving, environmental protection, cost reduction and labor expenditure;

6. It is convenient to replace the sensor to meet the different requirements of the overall heating or end heating of the bar;

2. Main application

1. High frequency quenching on the surface of gears (pulley shaft, drive wheel);

2. Quenching heat treatment and quenching machine tools for shaft parts;

3. Surface quenching of high frequency, medium frequency and super audio frequency of spline shaft (internal tooth spline);

4. Intermediate frequency surface quenching heat treatment for automobile axle shafts;

5. High frequency surface quenching heat treatment of boring bars;

6. Multi-station high frequency quenching heat treatment of machine tool spindle;

7. High frequency surface quenching of drill pipe and core pipe;

8. Surface induction hardening of straightening rollers with intermediate frequency and super audio frequency;

9. High-frequency induction surface quenching of the inner hole of sleeve-type parts;

10. High frequency surface quenching of machine tool guide rails;

11. High frequency surface quenching of large modulus worm;

12. Ultrasonic penetrating quenching of bearing rings;

13. Induction quenching heat treatment of automobile brake shoes;

14. The overall high frequency induction hardening of the sprocket;

15. Continuous induction quenching of the inner wall of the pump pipe of the concrete pump truck;

16. Induction hardening of engineering machinery pins, high frequency hardening of pins;

17. High-frequency heat treatment and machine tools of shock absorber connecting rods of automobiles and motorcycles;

18. Ultrasonic heat treatment of transmission shaft;

19. Induction heat treatment of ball head pin ball head;

20. High frequency continuous quenching heat treatment of toothed screw

21. High-frequency quenching of lifting ring lifting clip rigging.

22. High-frequency quenching heat treatment of agricultural machinery parts.

3. Scope of application

1. Application of ribbed induction annealing production line;

2. Heating and burning through the hot upsetting production line of round steel bar and steel column;

3. Induction heating of square steel;

4. The diathermy of the whole iron rod;

5. Red forging of standard parts (nuts and bolts);

6. Partial through-fire forging forming of pipes;

7. Hot forging of cold-drawn solid section steel, hot upsetting of the tie head of cold-drawn seamless steel pipe;

8. Induction hot upsetting of drill pipe ends;

9. Heating forging of automobile maintenance tools (socket wrenches);

10. Heating, stamping and bending of high-voltage power transmission and power line tower angle steel plates;

11. On-line warm upsetting forging of copper bars;

12. The application of heating and warm upsetting in the hot upsetting production line of the automatic steel ball and steel column upsetting machine.

13. Hot forging of rivets, spring bars and road studs for railway accessories

14. Heating of supporting accessories such as circlips and U-shaped cables;

15. Heating ears of leaf springs, etc.

4. Technical parameters

model | newRAC-120KW |

| Output Power | 120KW |

| Input voltage | 380v 50hz |

| Oscillation frequency | 10-50khz |

Pump Specifications | 2.2kw |

Cooling tower water flow | 15T/Hour |

pool | 2cube |

transformer | 50KW |

copper wire | 50cube |

浙公網(wǎng)安備 33038102331513號

浙公網(wǎng)安備 33038102331513號