The intermediate frequency melting furnace is used for melting and heating of steel, stainless steel, copper, aluminum, gold, silver and other metal materials; the melting capacity ranges from 1KG to 200KG.

The basic composition of the intermediate frequency melting furnace:

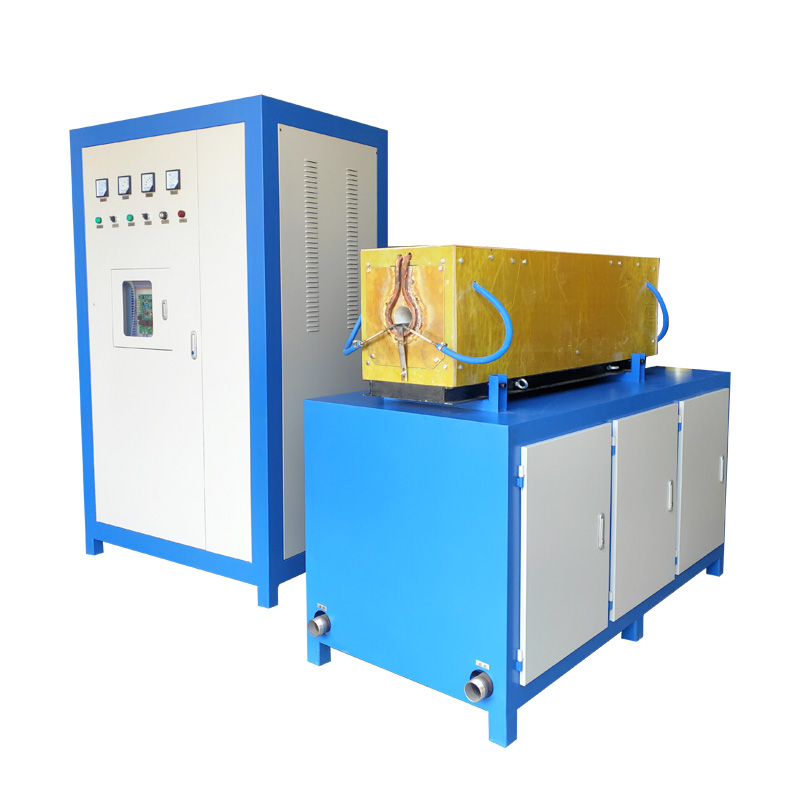

Including intermediate frequency power supply, compensation capacitor box and melting furnace, etc. According to different application requirements, it may also include infrared thermometers, temperature controllers and other devices; smelting furnaces are divided into three types: tipping smelting furnaces, top-out smelting furnaces and stationary smelting furnaces. The tipping type melting furnace can be divided into mechanical tipping furnace, electric tipping furnace and hydraulic tipping furnace according to the tipping method.

Features of intermediate frequency melting furnace:

(1) The intermediate frequency melting furnace is used for the melting of steel, stainless steel, copper, aluminum, gold, silver and other materials.

(2) The medium frequency smelting has a good electromagnetic stirring effect, which is beneficial to the uniformity of the smelting metal temperature and structure, and is beneficial to scum and reduce impurities;

(3) The frequency range is wide, from 1KHZ to 20KHZ, and the induction coil and matching compensation capacitor can be designed in consideration of the melting volume, electromagnetic stirring effect, heating efficiency, noise during operation and other factors to determine the output frequency;

(4) Compared with the thyristor intermediate frequency, the energy saving is at least 30% or more;

(5) The equipment is small in size and light in weight, and the melting capacity ranges from several kilograms to several hundred kilograms, with a wide range of options, suitable for factory production.

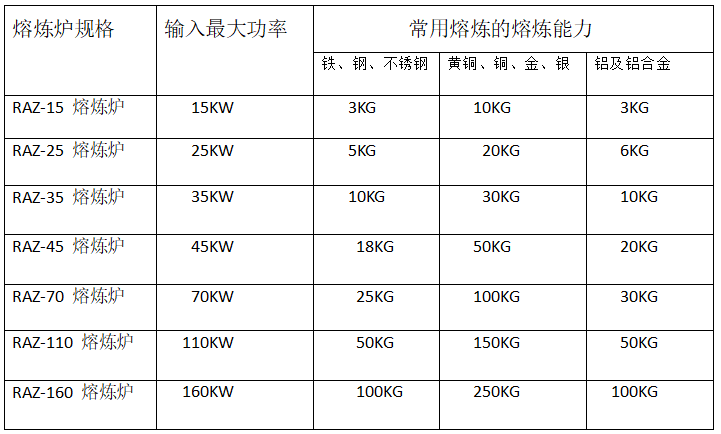

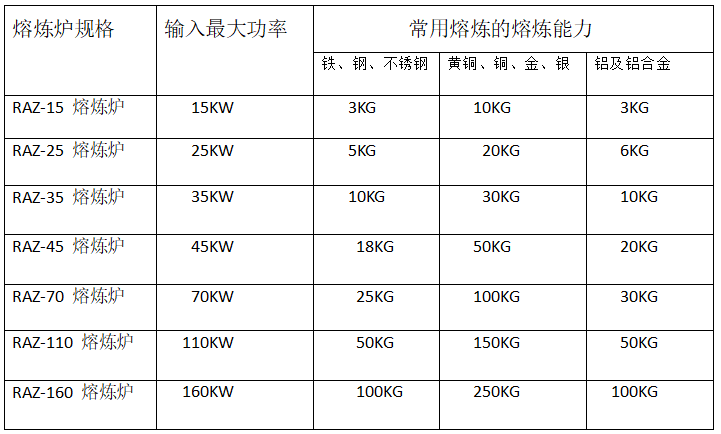

Main melting furnace specifications and heating capacity:

The maximum heating capacity of each melting furnace is listed in the table below. When the furnace is cold, the melting time of each furnace is 50--60 minutes, and when the furnace is hot, the melting time of each furnace is 20--30 minutes.

浙公網(wǎng)安備 33038102331513號(hào)

浙公網(wǎng)安備 33038102331513號(hào)